Steel, Alloy Steel, Stainless Steel, Heat Resistant Steel & SG Iron Castings Manufacturer

What We Do

Steel, Alloy Steel, Stainless Steel, Heat Resistant Steel & SG Iron Castings Manufacturer

Parikh Metacast Pvt. Ltd. is an ISO 9001:2015 certified company with 27 years of business experience in the manufacturing field with an associated company of Parikh Metaliks Pvt Ltd.

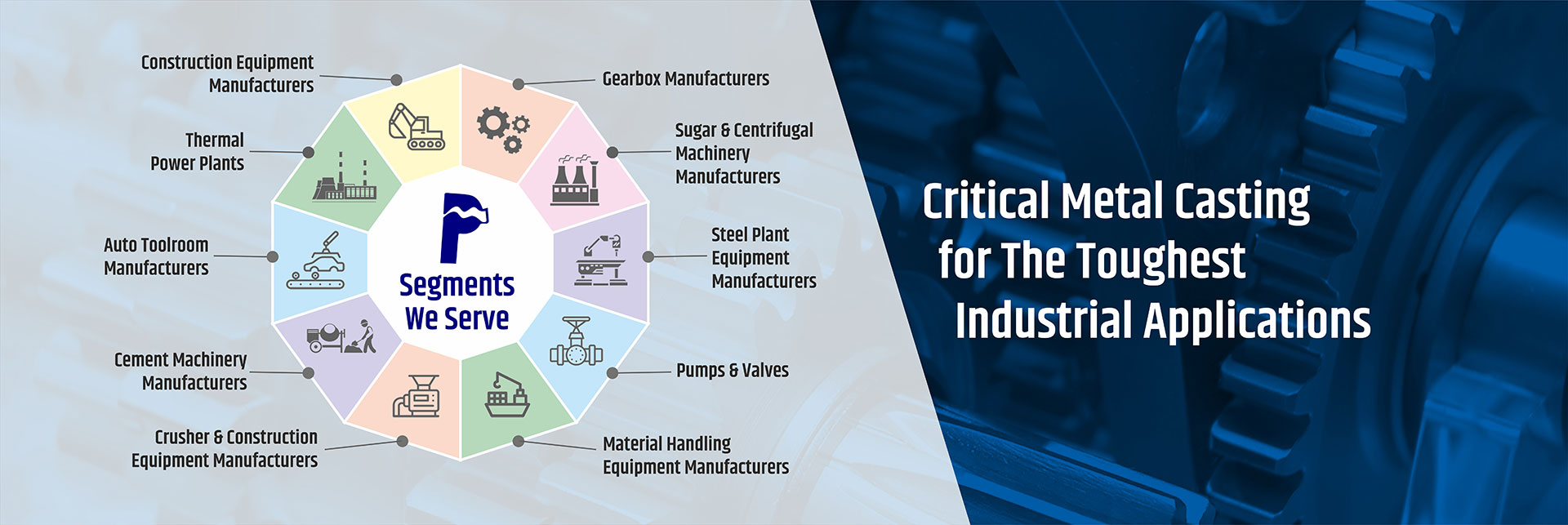

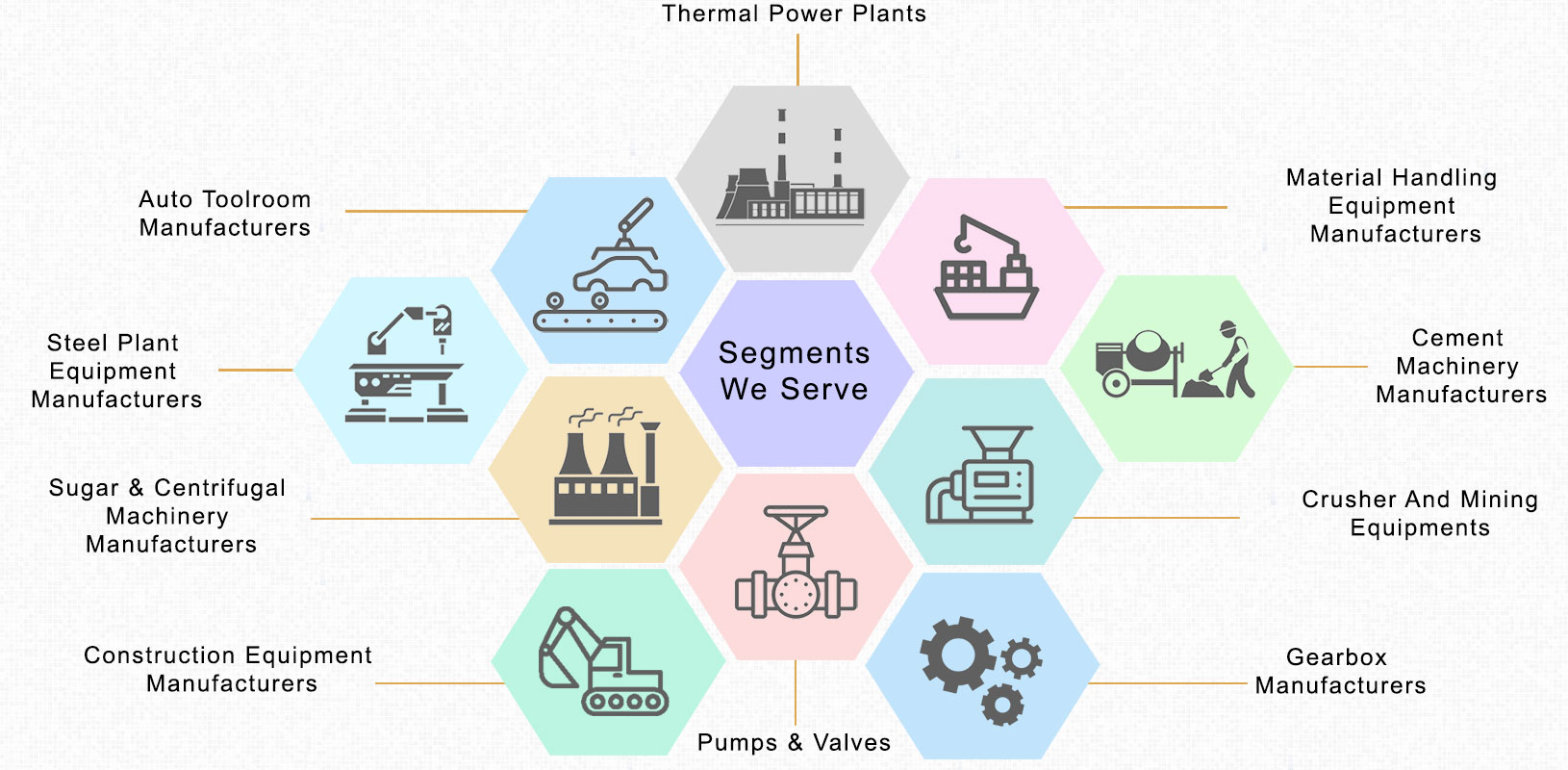

We manufacture Steel, Alloy Steel, Stainless Steel, Heat Resistant Steel and SG Iron castings ranging from 400 kgs to 7000 kgs single piece. We have been manufacturing & supplying various critical castings for industry segments like Crusher Manufacturers, Thermal power projects, Automobile Tool-room, Material Processing Industry, Valve Industry, Gearbox - Power & Transmission, Cement machinery, Steel plant equipment manufacturers, Food processing industry.

Our facilities are designed to meet variable requirements in terms of size, weight, criticality and grades of Steel and Ductile Iron. This enables us to take up challenging cast components having weight range up to 7000 kg and almost all grades of Steel, Stainless Steel, Alloy Steel & SGI.

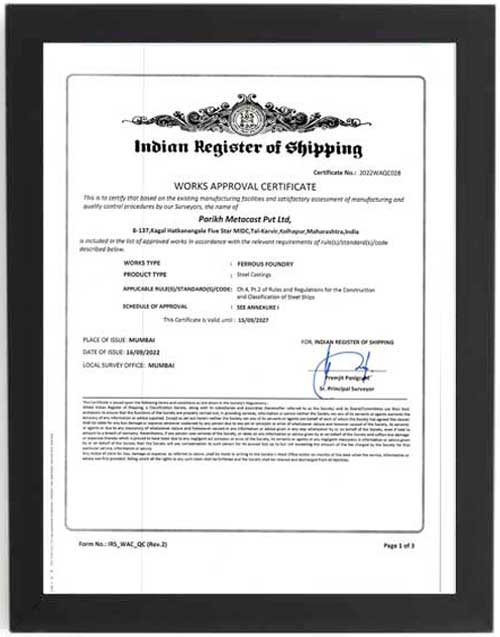

Majority of our components are being supplied in either proof or finish machined condition with relevant NDT testing (like UT, MPI, DP, RT) done. We are also approved by IRS (Indian Register of Shipping) for manufacture of steel castings for Marine/Shipbuilding projects & were certified ABS approved, currently renewal is under process.

Read MoreOur Foundry Capability

Material

Steel

Alloy Steel, Stainless Steel

Heat Resistant Steel

SG Iron (Ductile)

Casting Range

Weight : 400kgs to 7000 kgs

Value Addition

Heat Treatment

Machining

Auto Quenching (Water)

Sub-assembly

Annual Volume

Volume : 3600 MT

Segments We Serve

“Highly Complex Casting Parts, of Almost Any Size”

Our Steel Casting Foundry Products

SG dies for toolroom

Weight : upto 7MT

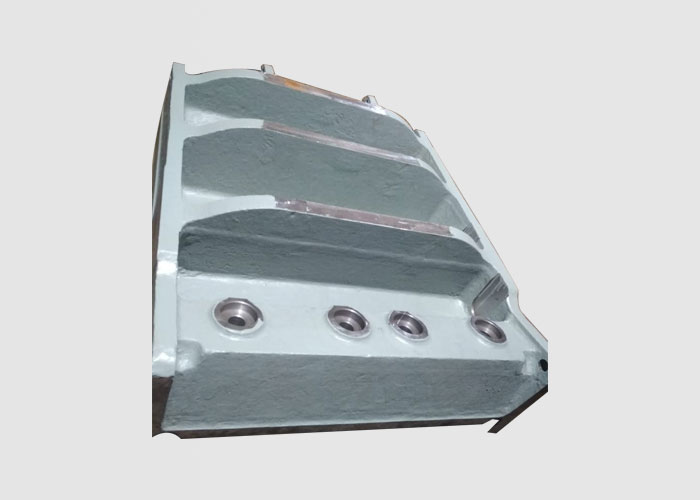

Crusher pitman

Weight : 1MT-7MT

GEAR

Weight : 1MT

Bowl support

Weight : 3MT

Alloy dies

Weight : upto 7MT

Cone heads for crusher

Weight : upto 7MT

Crusher Pitman

Weight : upto 7MT

SG Iron dies for Toolroom

Weight : upto 7MT

Various Cone sizes for crusher

Weight : upto 7MT

Alloy die casting Toolroom

Weight : 5MT

DN 450 valve body australia

Weight : upto 380kgs

DN 1200 valve body australia

Weight : 1.8MT

HRCS Segment for cement industry

Weight : upto 7MT

Various Frames from Crusher

Weight : upto 7MT

FURNACE TRAY ASSEMBLY HRCS for Steel plants

Weight : upto 7MT

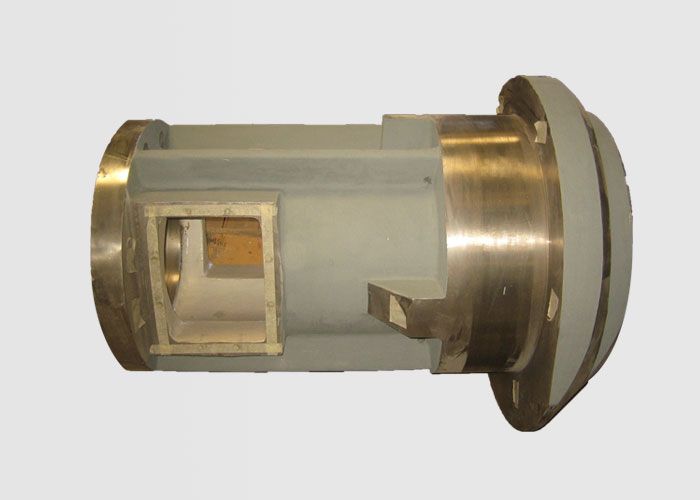

Piston Housing

Weight : 1818 Kg

Insert Die Casting

Weight : Upto 6000 Kgs

Dummy Bar Head

Weight : 691 Kg

Pulley-280

Weight : Upto 6000 Kgs

Crown Pinion

Weight : 1989 Kg

Bearing Housing

Weight : 3153 Kg

Rear End Frame

Weight : 1118 Kg

Bowl Casting

Weight : 3900 Kg

Front End Frame

Weight : 2551 Kg

Base Plate Casting

Weight : 613 Kg

Anchor Head Casting

Weight : 564 Kg

Centre Cone Casting

Weight : 163 Kg

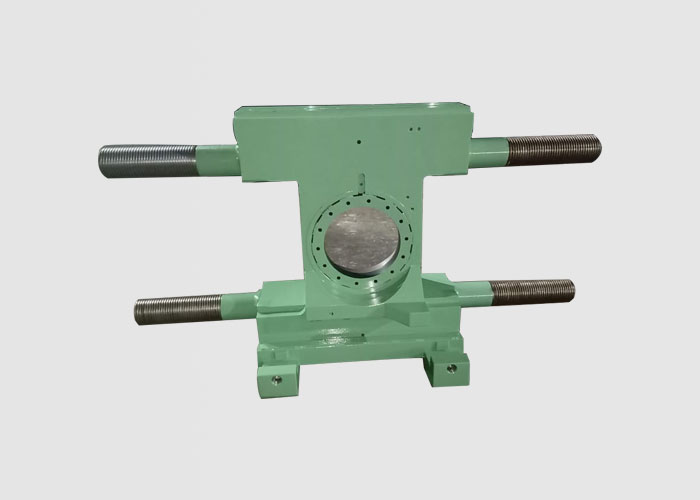

Middle Roll Chock

Weight : 1950 Kg

27+

Years of Legacy

140+

Expert Team

7000kg

Max Casting Range

4500MT

Annual Volume

Robust QMS Implementation

Our quality management system adheres to ISO 9000:2015 and we are committed to maintaining a Quality Management System (QMS) implemented at all levels of the company to assure that products and services meet our customers’ requirements and applicable regulatory requirements.

Our employees are trained to incorporate quality into the foundry process, allowing us to consistently deliver porosity-free, pressure-tight castings meeting dimensional tolerances.

We maintain a clean and well-lit facility conducive to quality production. The quality tools such as RCA, KAIZEN, waste management, 5S & visual factory are also being used for continual improvement

Product Quality, On Time Delivery and Satisfied customers are the result of our QMS culture.

Why Choose Us

-

End to End solution

Almost 80-90% of jobs are supplied in proof/finish condition, which helps our customers to save cost in Logistics, adding new vendors & get quality castings from a single source.

Robust QMS Solution

Our quality management system adheres to ISO 9000:2015 and we are committed to maintaining a Quality Management System (QMS).

-

Technical Expertise

We have 24+ years of Experience in Foundry Technology. We fully believe in solving customers' pain point & try to save his cost whether in terms of design, application, process etc.

-

Flexibility in weight & volume

We process components of flexible weights and volumes & based on the requirement of customer offer castings upto 7000 kgs single piece.

Skilled Manpower

At Parikh Metacast, we consistently train & upgrade the skills of 120+ employees to latest technologies of Foundry, who can provide solutions to our customers, as they are the one who are bringing the business & are growing with our customers

Recognition

We have vast experience of catering to casting requirements under 3rd party inspections

Best Small Business District Award 2017

Overall Business Excellence award from TLC